Retsch : 产品 : 粉碎设备 : 颚式粉碎仪

RETSCH jaw crushers are powerful forced-feed crushers, available in 7 sizes. They are used for sample crushing on a laboratory scale, but, depending on the model, can also

More

Jaw Crusher - an overview ScienceDirect Topics

Jaw-crusher Construction. Jaw crushers are heavy-duty machines and hence must be robustly constructed. The main frame is often made from cast iron or steel, connected

More

Influence of jaw crusher parameters on the quality of

2020.6.1 The interest of the current research is to conduct full-scale tests with jaw crushers in the primary crushing stage, to gain knowledge about how a single crushing

More

Jaw Crusher SpringerLink

2023.6.21 Jaw crusher is crushing equipment that works with two jaw plates, one fixed and the other movable. The movable jaw plate approaches the fixed jaw plate

More

Jaw Crusher - ScienceDirect

2016.1.1 Jaw crushers are designed to impart an impact on a rock particle placed between a fixed and a moving plate (jaw). The faces of the plates are made of hardened

More

(PDF) Influence of jaw crusher parameters on the

2020.3.19 PDF A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on... Find, read and cite all the research...

More

Evaluation of blast fragmentation effects on jaw crusher

2021.9.21 Jaw and gyratory crushers are the most common types of primary compression crushers. Each applies a compressive force to rock particles as they come

More

Failure rate analysis of Jaw Crusher: a case study Sādhanā

2019.1.2 4 Citations Explore all metrics Abstract Failure of crusher components has considerable influence on the productivity of a crushing plant. In order to improve

More

Industrial Solutions Jaw crushers - ThyssenKrupp

2022.11.21 Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are

More

Jaw Crusher SpringerLink

2023.6.21 The moving jaw rotates around the eccentric axis as well as swings around the same center (Fig. 2).By removing the moving jaw suspension shaft and the front toggle plate of simple pendulum jaw crusher, and suspending the moving jaw on eccentric shaft to combine the connecting rod and the moving jaw into whole, a compound pendulum jaw

More

Types of Crushers: What You Need to Know - Machinery

The demand for large-mouthed jaw crushers skyrocketed as the industry began to understand their potential as primary crushers in rock quarries. Through Thomas A. Edison’s research and development, giant machines were innovated and placed around the United States. Smaller-sized jaw crushers were also developed as secondary and tertiary crushers.

More

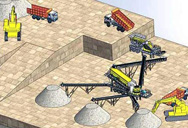

Mobile crushers and screens - SRP

Mobile crushers and Screens. We offer a wide range of mobile crushers and screens, both tracked and wheeled, to help you process rock in the toughest conditions. This selection includes jaw crushers, impactors, cone

More

Jaw crusher EB FLSmidth

Jaw Crusher EB 16-12 Pro with a capacity range of 400 – 1,200 tph; Jaw Crusher EB 14-11 Pro with a capacity range of 300 – 950 tph; Key benefits. High-performance jaw crushing with great energy saving potential. With our EB series, you benefit from a crushing solution that has high performance and durability in its DNA. We designed every ...

More

What Are Jaw Crushers and How Do They Work? Oreflow

2019.3.28 In a double-toggle jaw crusher, the moving crusher jaw is driven by the eccentric shaft that moves the front and rear toggles up and down. Each shaft revolution causes the moving crusher jaw to close at the downstroke and open up during the upstroke. The toggle is kept in place by spring-loaded tension rod.

More

Jaw Crushers – MEKA

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other makes an eccentric movement. There are also primary and secondary types of these crushers. Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all ...

More

Type of crushers and their difference - JXSC Mining

2019.12.10 Jaw crusher is used as primary crusher, it’s reduction ratio is usually 6:1. It uses compressive force to break the material, this mechanical pressure is achieved by the two jaws of the crusher. It is called a jaw crusher because it works the same was a human jaw does-food goes into your mouth and your bottom jaw pushes the food up against ...

More

jaw crusher - 英中 – Linguee词典

大量翻译例句关于"jaw crusher" – 英中词典以及8百万条中文译文例句搜索。 梯形磨粉机主要由主机,减速机,浓缩粉,引风机,除尘器,管道装置,集成商和电机组成,磨等全系 列 包括 颚式 破碎机, 斗 式 提升 机,磨减速机,Vibraing给料机,主要框架,鼓风机,粉选矿厂,粉收集系统,管道设备和 ...

More

Rock Crushers, Stone Crushers, Screening and Crushing

CJ412. Capacity (by hour) 165 - 790 mtph (182 - 871 stph) Feed opening. 1,200 x 830 mm (47 x 33 in.) mm. Motor power. 132 kW (200 hp) Sandvik crushing and screening equipment. Unrivaled jaw crushers, cone crushers, gyratory crushers, impact crushers and more for mining and construction applications.

More

Jaw Crushers - Astec

2024.1.24 Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. Our diverse line of industry-leading jaw crushers offers producers the latest in jaw crushing technology ...

More

Crushing - Metso

The crushers are built to perform with the lowest cost per ton, featuring a unique combination of crusher cavity design, crushing forces, reliability and safety. ... Spare parts for gyratory, jaw, cone and impact crushers for the

More

Sandvik QJ341 Mobile Jaw Crusher – World Leading Jaw Crusher

400 mtph (440 stph) Sandvik QJ341 mobile jaw crusher is the ideal solution for a wide range of applications. Equipped with a C12 jaw crusher, a powerful and fuel-efficient engine, it is designed to tackle the most difficult operations. QJ341. Features.

More

Modeling of the Interaction between a Rock Being Processed

2021.3.10 Abstract In this article, a model of the interaction between the jaw of a vibratory jaw crusher with the rock under processing in the form of a lump material is considered. To describe the motion of the rock and its sequential fracture into finer fragments, the crushing chamber is divided into zones of equal height. In each current

More

Jaw Crushers Heavy Duty Terex Finlay

6 天之前 LJ-130 Hybrid. The Finlay® LJ-130 hybrid mobile jaw crusher is the largest mobile jaw crusher in our range and has been developed for large-scale quarry and mining operations.The plant’s electrically driven power systems provide significant cost advantages and environmental efficiencies. The machine features a robust Terex 1300 x 1000mm (51 ...

More

Jaw Crusher Primary Crusher in Mining Aggregate - JXSC

JXSC Jaw Crushers Advantages Features. 40 years of manufacturing and engineering experience keep us innovative and knowledge in the rock break machines and its applications, which thus provide reliable industry rocks crushers and solutions for every customer using jaw crusher manufacturers JXSC machines to meet their production

More

Crushers - All crusher types for your reduction needs - Metso

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

More

MC 110i EVO2 Mobile jaw crushers Kleemann - Wirtgen

The jaw crusher MOBICAT MC 110 EVO2 is used for the precrushing of almost all natural rock and in recycling. Compact dimensions, efficient prescreening, simple operation via SPECTIVE as well as impressive production output characterize the efficient key player. Continuous Feed System (CFS) for optimal crusher feeding.

More

What Are the Differences Between The 7 Types of Crushers?

2023.2.15 Jaw crusher crushes on half-cycle and favors arrested crushing. The fixed jaw crusher foundation needs to be rugged to overcome the working stress. For gyratory crusher, the outer circle represents the stationary bowl covered by the concave and the inner circle represents the main shaft covered by the mantle. The main shaft rests in the ...

More

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017.3.4 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the ...

More

Liner wear in jaw crushers - ScienceDirect

2003.1.1 The jaw crusher they used was choke fed with quartzite of size 8–11 mm, resulting in compressive force peaks of 6–13 kN per crushing cycle. Show abstract. The majority of the operating costs of commercial crushing are caused by the power consumption and the wear part maintenance. Better understanding of the variables

More

Crushing 101 – Different types of crushers for distinctive needs

2020.12.17 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

More

Used crushers for sale - Mascus UK

Parker 36 x 10 Jaw Crusher c/w Electric Motor #038; Cont. Riverside Machinery Ltd. Crushers • -, UK • Riverside Machinery Ltd. 12,000 GBP. Favorite. Riverside Machinery Ltd. 9. McCloskey J45. Blue Machinery ( Central ) Crushers • 2020 • 3410h • Northwich UK, UK • Blue Machinery ( Central ) POA.

More

How Does a Jaw Crusher Work Jaw Crusher

4 天之前 Jaw crushers have been around for nearly 200 years at this point and are one of the most “historic” crusher types. Because of this, jaw crushers have advanced technologically through the years to make them

More

K-JC503 Mobile Mini Jaw Crusher - Komplet America

4 天之前 The K-JC 503 mobile jaw crusher creates the best opportunities to save money on excavation and demolition waste removal by creating byproducts that can be repurposed. Our lightweight compact jaw crushers open doors to endless possibilities to reduce, repurpose, and recycle waste on-site. Contact our team to schedule an in-person

More

Crusher - an overview ScienceDirect Topics

13.3.1.1 Primary Crusher. Primary crushers are heavy-duty rugged machines used to crush ROM ore of (−) 1.5 m size. These large-sized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm. The

More

Jaw Crushers - Armstrong Equipment

The new quick-change jaw die system and quick-adjust hydraulic shim system provide more uptime. Combine these features with our well-known durability and you have a crusher that keeps you up and running. Reliability, quality, capacity, and ease of use—the new Terex® Cedarapids JS Series jaw crushers are designed to help you be more profitable.

More

Nordberg® C Series™ jaw crushers Proven reliability and

2021.7.16 Nordberg® C Series™ jaw crushers are designed to handle the toughest feed materials in the primary crushing stage. They have proven their performance in at least 10,000 reference cases since 1975, in applications including mining, quarrying, recycling and industrial minerals. They have the highest power ratings in each size class thanks to ...

More

Jaw Crushers Price, 2024 Jaw Crushers Price Manufacturers

The cost of a Jaw Crushers Price can vary widely depending on its size, capabilities, and complexity. Most of the price of Jaw Crushers Price ranges from US $ 516 to $ 450000 per Set. It's important to research and compare different models and features to find the best Jaw Crushers Price for your needs and budget. Q.

More

Trio® Crushing Equipment Weir

For jaw crushers, we supply a range of jaw dies and liners with a variety of teeth options to best suit the application. Gyratory Crushers. The pairing of our mantles with concave segments ensures maximum production, increased wear component life and reduced maintenance. Our gyratory crusher wear part offering includes accessories like rim ...

More

Jaw Crusher for Hard Materials DASWELL

2023.11.16 Daswell jaw stone crusher has a relatively firm frame and can work under high pressure. The weight of the equipment is about 15% heavier than other manufacturers, and the structure is stronger and more impact-resistant. 2. The crushing ratio of jaw crusher for sale is large and the product particle size is uniform.

More